Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

① High specific strength (tensile strength/density) (see picture), the tensile strength can reach 100-140kgf/mm2, while the density is only 60% of steel.

②It has good strength at medium temperature, and its service temperature is several hundred degrees higher than that of aluminum alloy. It can still maintain the required strength at medium temperature, and can work for a long time at a temperature of 450-500°C.Commonly used heat treatment methods include annealing, solid solution and aging treatment. Annealing is to eliminate internal stress, improve plasticity and structural stability, so as to obtain better comprehensive properties. Usually the annealing temperature of α alloy and (α+β) alloy is selected at 120-200°C below the (α+β)-→β phase transition point; solid solution and aging treatment are rapidly cooled from the high temperature zone to obtain martensite α′ Phase and metastable β phase, and then keep warm in the medium temperature zone to decompose these metastable phases to obtain fine dispersed second phase particles such as α phase or compound, so as to achieve the purpose of strengthening the alloy. Usually (α+β) alloys are quenched at 40-100°C below the (α+β)-→β phase transition point, and metastable β-alloys are quenched at 40-80°C above the (α+β)-→β phase transition point conduct. The aging treatment temperature is generally 450-550°C. In addition, in order to meet the special requirements of the workpiece, the industry also adopts metal heat treatment processes such as double annealing, isothermal annealing, β heat treatment, and deformation heat treatment.

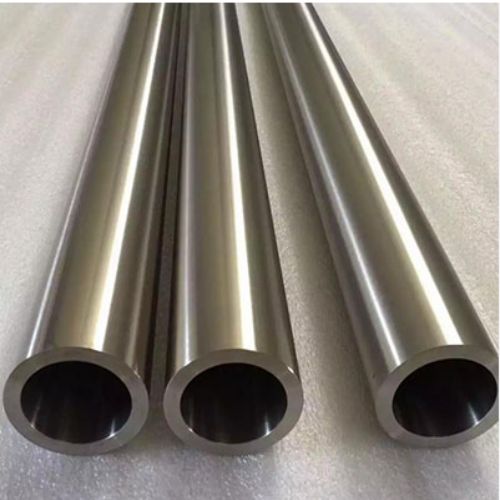

We can offer Stainless Steel Pipe products, including Stainless Steel Capillary Pipe, Stainless Steel Precision Pipe, Stainless Steel Seamless Pipe , Stainless Steel Sanitary Pipe , Thick Wall Stainless Steel Pipe, Stainless Steel Bright Tube , Stainless Steel Needle Tube , Stainless Steel Fine Tube , Stainless Steel Coil , Welded Stainless Steel Pipe , Stainless Steel Industrial Pipe, Stainless Steel Round Tube , Medical Stainless Steel Tube , Stainless Steel Thin Wall Tube , Stainless Steel Shaped Tube , Stainless Steel Elbow , Stainless Steel Snake Bone Tube, Stainless Steel Decorative Tube, Stainless Steel Electronic Cigarette Tube, Stainless Steel Tube Processing, Copper Pipe , Titanium Alloy Tube , Aluminum Tube , and so on.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.